Unique Registration Number: GSIC-459

Innovator Name:

Omer Qabeer (Leader)

Seattle Rodrigues

Samuel Rodrigues

Harshad Shet Dessai

Rahul Pawar

Contact No: +919284206586

Project Objective:

- Personalization and designing of food.

- Time and Energy saving to make food in faster manner.

- Food waste Reduction.

- Food reproducibility is possible using a 3-D printer.

- Meal composition adapted to individual diets

Contact Email: mohdomerqabeer@gmail.com

Abstract:

The aim of this project is to automate the process of cake making and baking on a single touch with the help of a 3-D printer. The application of 3-D printer in mechanical engineering is mostly in the field of additive manufacturing of parts and components in industries but the use of this printers in food industries is seldom. The problem with traditional method of baking cakes is time consuming and also demands human assistance to make and design the cake. This project work can eliminate these existing problems and can also cater the big markets of cloud kitchen which is the future.

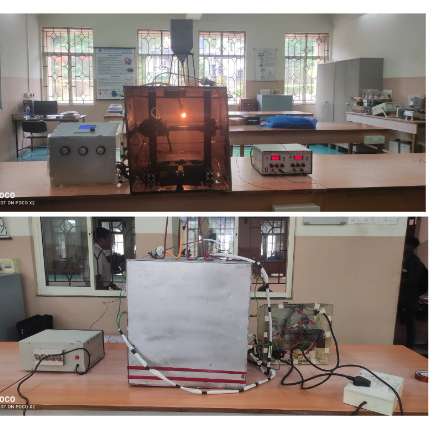

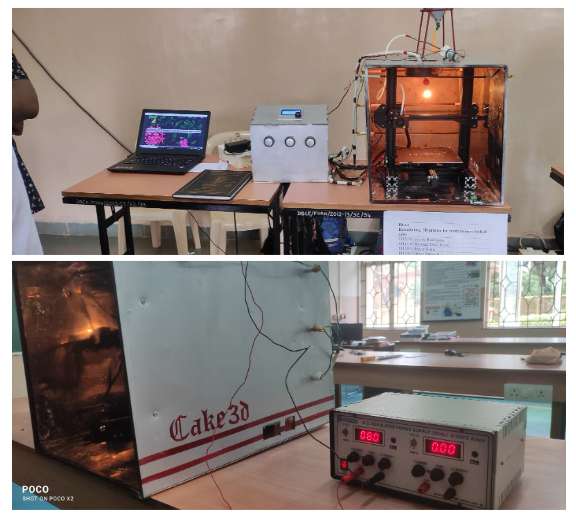

The project work consists of a 3-D printer (Creality Ender 3), pump, hopper, chamber for baking. The hopper is placed on top of the chamber where the user pours the cake batter in it. One can add their custom design via a designing software in the form of G-code or can insert a micro-SD card which has the design in it and start the printer. Once the input is provided the printer bed and the chamber which has heating elements start heating. The printer prints on the bed of the printer, layer by layer while also getting cooked in the process. The provision is also kept to make the printer wireless and not just printing of cakes but pancakes too

Project Outcome/result/findings:

- Customization and designing of the foods.

- Repeatability of the same model.

- The shifting of the components inside the cabinet was done successfully to prevent the

electronic components from getting damaged by the heat of the chamber and from the

spillage of the batter also. - A higher capacity hopper was made to store more batter.

- Optimum cake batter consistency was achieved from the batter to flow from the pump

Innovative Approach: (in 50 words)

- Editing the frame.

- Designing and fabrication of food grade chamber with the required insulations.

- Addition of heating element in the chamber

- Disassembly of the electronic parts and Shifting of the components to a new cabin.

- An air blower for distribution of hot air uniformly.

- Insulation of the wires