Innovator Name:

Nathan Mazarello

Amston Sanches

Ashish Tarale

Chirag Naik

Lemuel De Cunha

Contact No: +917411357170

Project Objective:

- To develop a composite lamina made up of natural fibres and CNSL (Bio-based matrix).

- To test the lamina and obtain its tensile and flexural properties.

- To perform statistical analysis of the results obtained from the tests.

- To carry out analysis for correlating obtained results

Contact Email: samantgaurish@gmail.com

Abstract:

Composites have gained prime importance due to their high strength-to-weight ratios that make

them applicable for various useful applications as compared to traditional metals.

However, with certain advantages, these composites are a threat to the environment due to their

toxic nature and non-biodegradability.

Hence, a heightened need of the hour is producing green composites made of naturally available

fibers and bonding matrix materials.

This project aims to produce green composites of three different natural fibres (Bamboo, Coconut

Midrib and Areca leaf sheath), locally available in and around Goa, bonded together by Cardanol

resin, a derivative of cashew nut shell oil.

Silicon dioxide nanoparticles, graphene nanoparticles and single walled carbon nanotubes are

added to increase its mechanical properties.

Prior to composite manufacturing, the fibers are subjected to chemical treatments such as

alkali treatment (NaOH), Silane treatment and Benzoyl peroxide treatment to improve bonding

properties between fiber and matrix, thereby increasing mechanical properties.

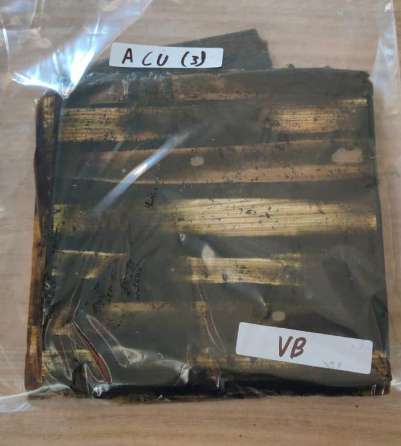

A total of twenty seven composite samples are produced, where nine are produced by Compression

Moulding, nine by vacuum bagging technique and the rest nine by hand layup process.

All samples are tested to obtain tensile and flexural properties by performing the tensile test and

flexural test.

The obtained properties are statistically analyzed and compared with properties of already

produced green composites

Project Outcome/result/findings:

- Obtaining twenty-seven different composites manufactured by varying fibre percentage,

nanofillers and manufacturing methods. - Obtaining tensile and flexural properties by performing mechanical tests.

- Theoretical analysis of composite in software such as MATLAB, Ansys and COMSOL.

- Comparative study of each composite based on the different types of fibres used