Imagine having a machine that could make anything you wanted. sounds interesting, doesn’t it? a 3d printer can help make this possible, it involves the creation of three-dimensional objects from digital data. there are a variety of things you can 3d print, be it action figures to products that you’d use in your day-to-day life.

The 3D printer begins by constructing parts from different raw materials and builds them up layer by layer. Very little waste is created along the way.

3D printing centres around layering materials like plastics, composites and biomaterials to create objects. Though it’s seen as an up-and-coming technology, 3D printing isn’t actually that new. It was originally introduced back in the 1980s.

The History Of 3D Printing

The idea of 3D printing kicked off when Hideo Kodama was the first to write an explanation of how materials called photopolymers hardened when exposed to UV light so that they can be utilized to rapidly create solid prototypes. Although he created the foundation for 3D printing with his article, he wasn’t the first to construct a 3D printer.

It was Charle’s Hull who designed and created the first 3D printer in 1984. During this, he had been working for a company that used UV lamps to fashion tough, durable coatings for tables when he hit on the idea to take advantage of ultraviolet technology to make small prototypes. Hull went on to break new ground in 3D printing technology by inventing the first ever 3D printer also known as stereolithography (SLA or SL). SLA is special because it allows designers to create their 3D models using digital data files. Later they upload these files to the printer to produce real physical 3D objects, one layer at a time.

He went on and commercialized his ground-breaking new technology in 1986, he co-founded 3D Systems, a company that commercialized his ground-breaking technology. Today, 3D systems continue to innovate with a full line of professional and production 3D printers, cutting-edge software solutions, a wide range of materials, as well as user-friendly desktop 3D printers for the expanding hobby and entrepreneur markets.

Types Of 3d Printing

It’s safe to say that 3D printing is most often used for prototyping. Its ability to quickly manufacture a single part enables product developers to validate and share ideas in a cost-effective manner.

Rapid prototyping, modelling, and specialized one-off goods are not the only applications for 3D printing that are cool. It is a vital component of the “fourth industrial revolution,” which has the power to transform the way in which production and consumption are connected.

Determining the purpose of your prototype will inform which 3D printing technology will be the most beneficial. For this, we should understand a few basic types of 3D printers.

1. Stereolithography (SLA) 3D Printing

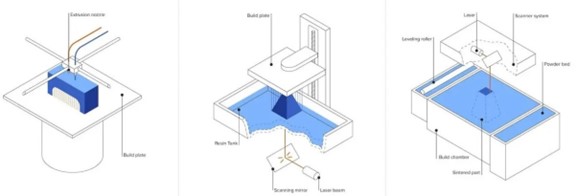

Stereolithography (SLA) was one of the very first 3D printers introduced in the 1980s. In stereolithography, liquid resin is cured by a light source-a laser or projector to form a solid object. These machines are all based on the same principle, using a light source to cure the liquid resin into hardened plastics. The main physical differentiation lies in the arrangement of the core components, such as the light source, the build platform, and the resin tank. What makes SLA different from other types?

Here the laser cures the photopolymer resin. It has a high versatile material section like glass and ceramic or imbued with mechanical properties like high heat deflection temperature or impact resistance.

It is great when you require high resolution, accuracy, and minute details.

It’s best for tooling, moulds, and functional prototypes.

2. Selective Laser Sintering (SLS) 3D Printing

Selective Laser Sintering (SLS) is an additive manufacturing process that belongs to the Powder Bed Fusion family. For many years, engineers and manufacturers have favoured SLS 3D printing.

The technology is perfect for a variety of applications, from rapid prototyping to custom manufacturing, because of its low cost per part, high productivity, and well-established material.

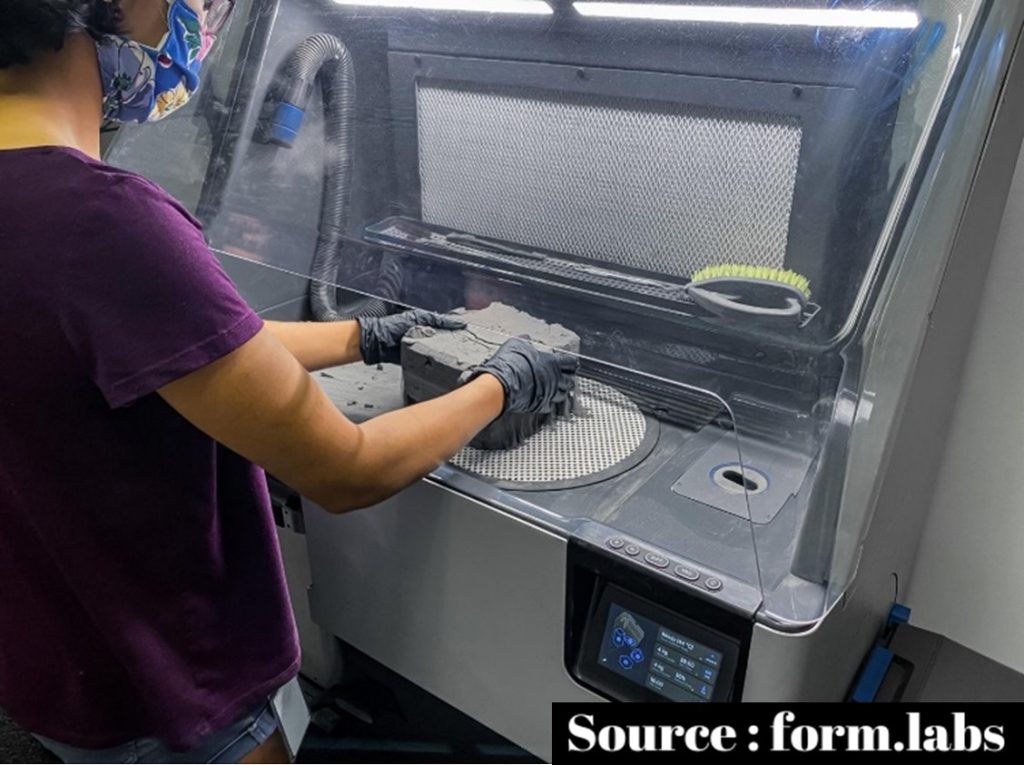

SLS has one of the most unique yet interesting printing processes. It’s where the power source is a laser and the material is a powder usually nylon. The laser centres a layer of nylon powder that is then dropped a little bit and another very small layer of powder is brought over. The process repeats for each layer until the parts are complete.

SLS allows us to recycle and reuse materials for the following projects, making it one of the least wasteful production processes in the world. You can remove the finished parts from the build chamber once a print is finished, separate them, and clean off the extra powder. Any excess powder remaining after the part is filtered to remove larger particles can be recycled.

3. Fused Deposition Modeling (FDM)

At the consumer level, fused deposition modelling (FDM), commonly referred to as fused filament fabrication (FFF), is the most popular 3D printing technology. FDM 3D printers function by melting thermoplastic filaments like ABS (Acrylonitrile Butadiene Styrene) and PLA (Polylactic Acid) and applying them layer by layer to a build platform through the use of heated nozzles. Until the portion is finished, one layer at a time is applied.

FDM 3D printers are ideal for quick and inexpensive prototyping of simple parts, such as those that would generally be machined, as well as for creating small proof-of-concept models.

FDM is not the ideal option for printing elaborate drawings or parts because it has the lowest resolution and accuracy when compared to SLA or SLS. But FDM is the most ideal for basic proof-of-concept models & Simple prototyping.

Applications and Uses of 3D Printing In Industries:

3D printing as technology has emerged greatly in various industries. Major industry companies have begun using this technology for everything from fully functioning cars to various tools.

It has always provided new opportunities to different sectors be it from the Healthcare industry to the fashion industry.

Medical / Healthcare Industry:

Recently additive manufacturing showcased ed its practical versatility becoming a powerful tool in tackling some of the unprecedented challenges posed by covid19.

It has helped to supply health workers with personal protective equipment and patients with ventilators.

Nowadays, there are many patients who have various 3D-printed replacements implanted inside their bodies. One popular example is the application of knee and shoulder joint replacements to patients.

Architecture industry:

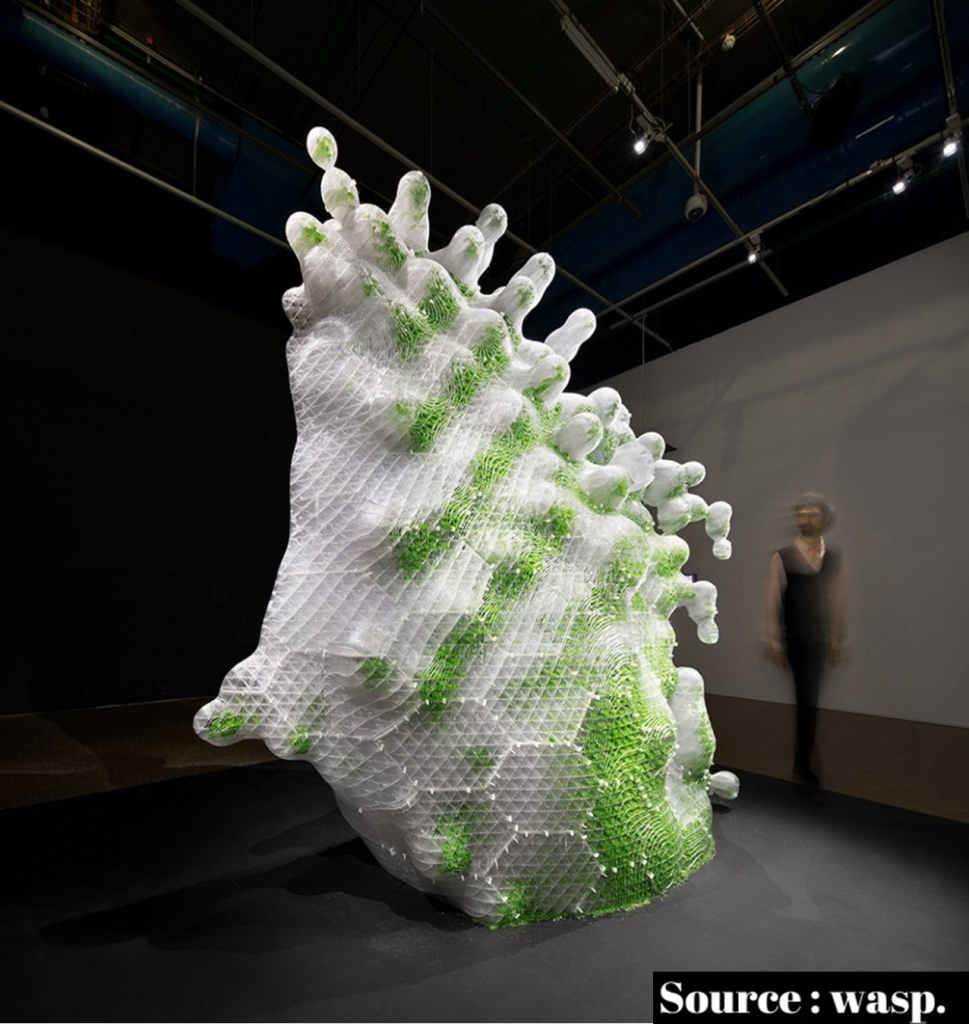

Building models are produced using 3D printing in the fields of architecture and construction. In the past, architects used just CAD software to design buildings. CAD files can now be transformed into 3D printable files with the use of 3D printing.

By using quicker and less expensive prototyping, architects and engineers may readily adapt 3D structures and explore various market potentials. Some benefits of 3D printing in the architecture and construction industry include the reduction of material waste and the invention of innovative shapes and structures.

What tips are there for hiring a car in Barcelona?

Yes, correctly.

I am final, I am sorry, but it does not approach me. I will search further.